MONAHAN FILAMENT FIBER PROPERTIES

MFI produces fibers in a wide variety of materials, in several different shapes, in many different sizes, and in almost any color. We have prepared this section on Fiber Properties to distinguish between them. The following table compares some of the properties in a general way, followed by definitions and by information in detail.

PRODUCT |

Specific Gravity |

Melting Point (°F) |

Tensile Modulus (k-psi) |

Typical Elongation (%) |

Tensile Strength (k-psi) |

Flicking Action (springiness) |

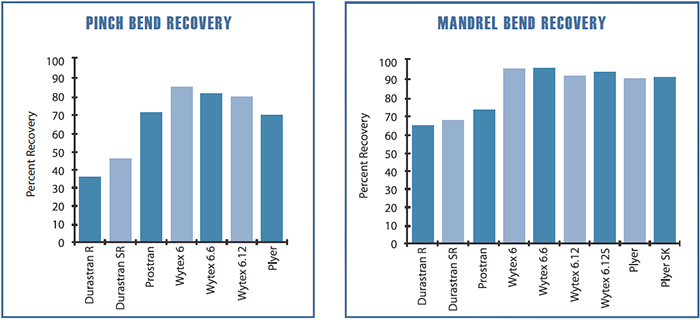

% Bend Recovery .008" Fiber |

Typical Ovality .008-040" |

|---|---|---|---|---|---|---|---|---|

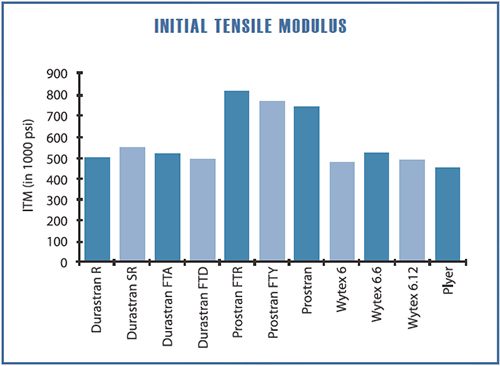

| Durastran® R | 1.05 | 350 | 500 | 54 | 16 | Excellent | 65 | 1.04-1.20 |

| Durastran® SR | 1.08 | 250 | 550 | 47 | 13 | Excellent | 70 | 1.03-1.15 |

| Durastran® FTA | 1.00 | 250 | 520 | 51 | 24 | Excellent | 75 | 1.03-1.18 |

| Durastran® FTD | 1.00 | 320-350 | 500 | 62 | 20 | Excellent | 74 | 1.04-1.20 |

| Durastran® FTR | 0.93 | 320 | 810 | 20 | 58 | Good | 71 | 1.05-1.50 |

| Durastran® FTY | 0.93 | 320 | 765 | 25 | 59 | Good | 71 | 1.05-1.50 |

| Prostran® | 0.90 | 320 | 740 | 17 | 53 | Good | 75 | 1.02-1.40 |

| Polyethylene | 0.92 | 230 | 60 | 100 | 9 | Poor | NA | 1.02-1.20 |

| PVC | 1.35 | 200 | 515 | 60 | 25 | Excellent | 60 | 1.01-1.10 |

| PPS | 1.35 | 545 | 560 | 40 | 59 | Poor | 67 | 1.02 |

| Wytex® 6 | 1.14 | 410 | 480 | 36 | 53 | Excellent | 97 | 1.02-1.15 |

| Wytex® 6.6 | 1.14 | 495 | 520 | 36 | 48 | Excellent | 97 | 1.01-1.10 |

| Wytex® 6.12 | 1.06 | 410 | 480 | 36 | 42 | Excellent | 93 | 1.01-1.10 |

| Wytex® 6.12S | 1.06 | 410 | 500 | 52 | 55 | Excellent | 95 | 1.01 |

| Plyer® | 1.30 | 430 | 445 | 36 | 31 | Excellent | 92 | 1.01-1.10 |

| Plyer® SK | 1.26 | 430 | 550 | 52 | 55 | Excellent | 94 | 1.01 |

PRODUCT |

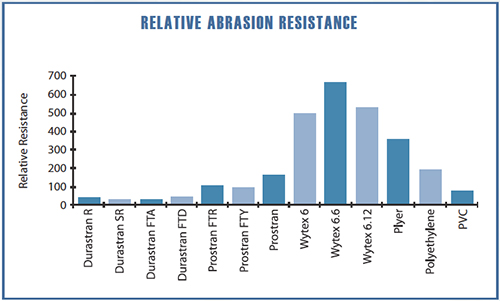

Relative Abrasion Resistance |

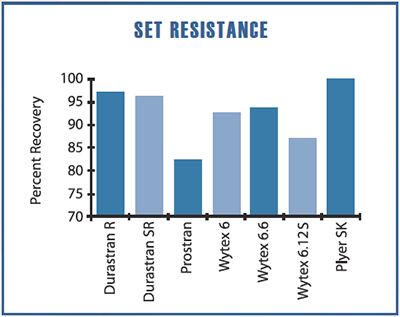

Set Resistance |

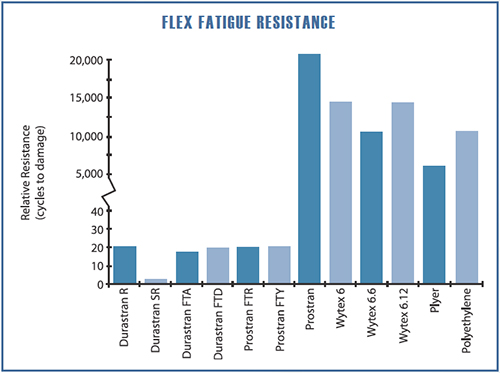

Relative Fatigue Flex Resistance |

Water Absorption % Max. |

Retention of Stiffness in Water |

Sun Light & UV Light Resistance 1 |

Hi-Temp Oxidation Resistance 2 |

General Solvent Resistance |

|---|---|---|---|---|---|---|---|---|

| Durastran® R | Poor | Excellent | Poor | <0.03 | Excellent | Fair | NA | Poor |

| Durastran® SR | Poor | Excellent | Poor | 0.5 | Excellent | Fair | NA | Fair |

| Durastran® FTA | Poor | Good | Poor | 0.4 | Excellent | Poor | NA | Fair |

| Durastran® FTD | Poor | Good | Poor | <0.03 | Excellent | Poor | NA | Poor |

| Durastran® FTR | Fair | Fair | Poor | <0.1 | Excellent | Poor | Poor | Excellent |

| Durastran® FTY | Fair | Fair | Poor | <0.1 | Excellent | Poor | Poor | Excellent |

| Prostran® | Fair | Fair | Best | <0.1 | Excellent | Poor | Poor | Excellent |

| Polyethylene | Fair | Fair | Good | <0.1 | Excellent | Poor | NA | Excellent |

| PVC | Poor | Excellent | Fair | <0.1 | Excellent | Good | NA | Fair |

| PPS 3 | Fair | Good | Good | 0.01 | Excellent | Good | Superior | Superior |

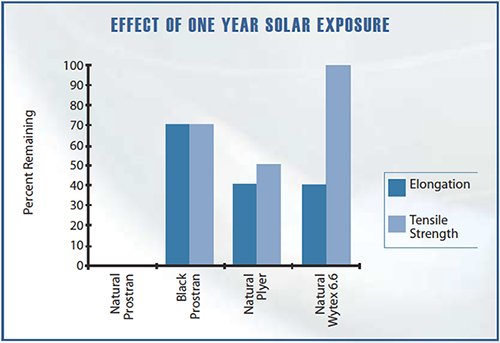

| Wytex® 6 | Excellent | Good | Excellent | 9 | Poor | Fair | Fair | Excellent |

| Wytex® 6.6 | Excellent | Good | Excellent | 9 | Poor | Fair | Fair | Excellent |

| Wytex® 6.12 | Excellent | Good | Excellent | 3 | Good | Fair | Fair | Excellent |

| Wytex® 6.12S | Excellent | Good | Excellent | 3 | Good | Fair | Fair | Excellent |

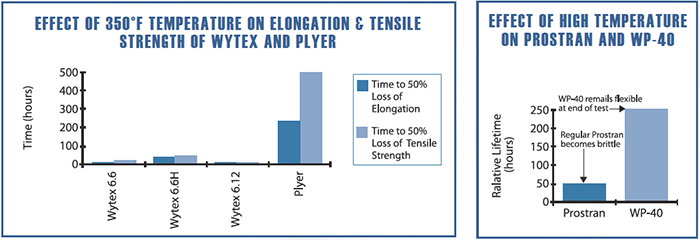

| Plyer® | Good | Good | Good | 0.5 | Excellent | Fair | Best | Excellent |

| Plyer® SK | Good | Good | Good | 0.5 | Excellent | Fair | Best | Excellent |

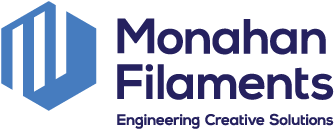

- Sunlight and UV resistance may be greatly improved by the addition of black pigment or UV inhibitors.

- High temperature oxidation resistance may be greatly improved by oxidation inhibitors.

- PPS can be used continuously for long time periods at temperatures up to 200-220°C (392-428°F), in contrast Plyer and Plyer SK are limited to about 150°C. PPS has good set resistance at very high temperatures where other materials, which have excellent set resistance at room temperature, fail to have any recovery whatsoever. PPS does not burn (it is a non-halogenated V-0 material requiring no flame retardant). It has superior solvent resistance. PPS is especially good in high temperature steam, fuels and oils. It has good resistance to most acids. Special grades may be used for medical handling and food contact applications. These special grades are in compliance with ISO 10993, USP Class IV, and are included in the Drug and Device Master Files at the FDA. This grade also complies with Food Contact Notification (FCN-No. 40) for repeat use applications.